-

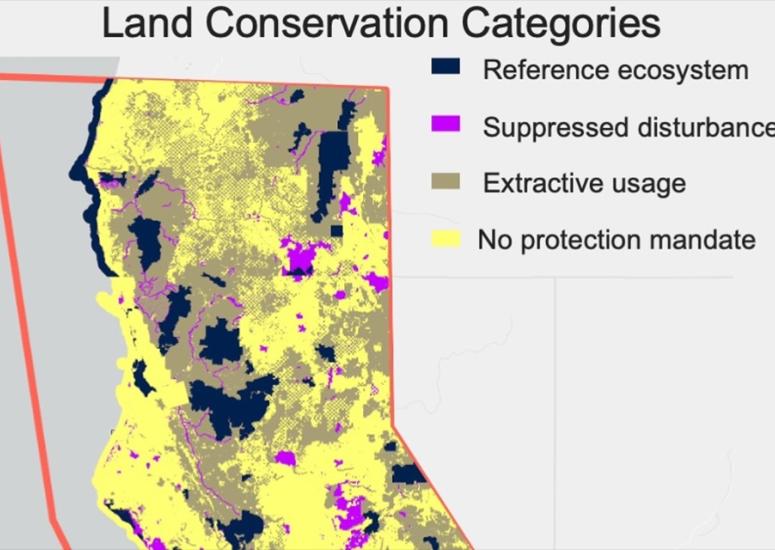

Satellite observations provide insight into post-wildfire forest recovery

Using satellite observations to evaluate forest recovery following a wildfire could be an innovative, cost-efficient way to assess the effectiveness of land management practices, according to research published earlier this year.

- Data

-

NSF NCAR C-130 flying low over the New York City area starting today

From July 16 through August 31, a C-130 research aircraft will periodically fly over the tri-state area to collect data about air quality.

- Air Quality

-

Steering clear of turbulence

A prototype turbulence detection system is designed to guide aircraft worldwide from areas of rough air.

- Weather

-

Jothiram Vivekanandan named honorary fellow of the Indian Meteorological Society

An expert in polarimetric, dual-wavelength, and phased array radar technologies, Vivekanandan has collaborated extensively with Indian scientists to advance understanding of monsoon precipitation.

- Organization,

- Weather

-

Boulder’s winds aren’t what they used to be

Peak wind gusts in Boulder and across the Front Range have weakened in recent decades, causing less damage.

- Weather